DESIGN

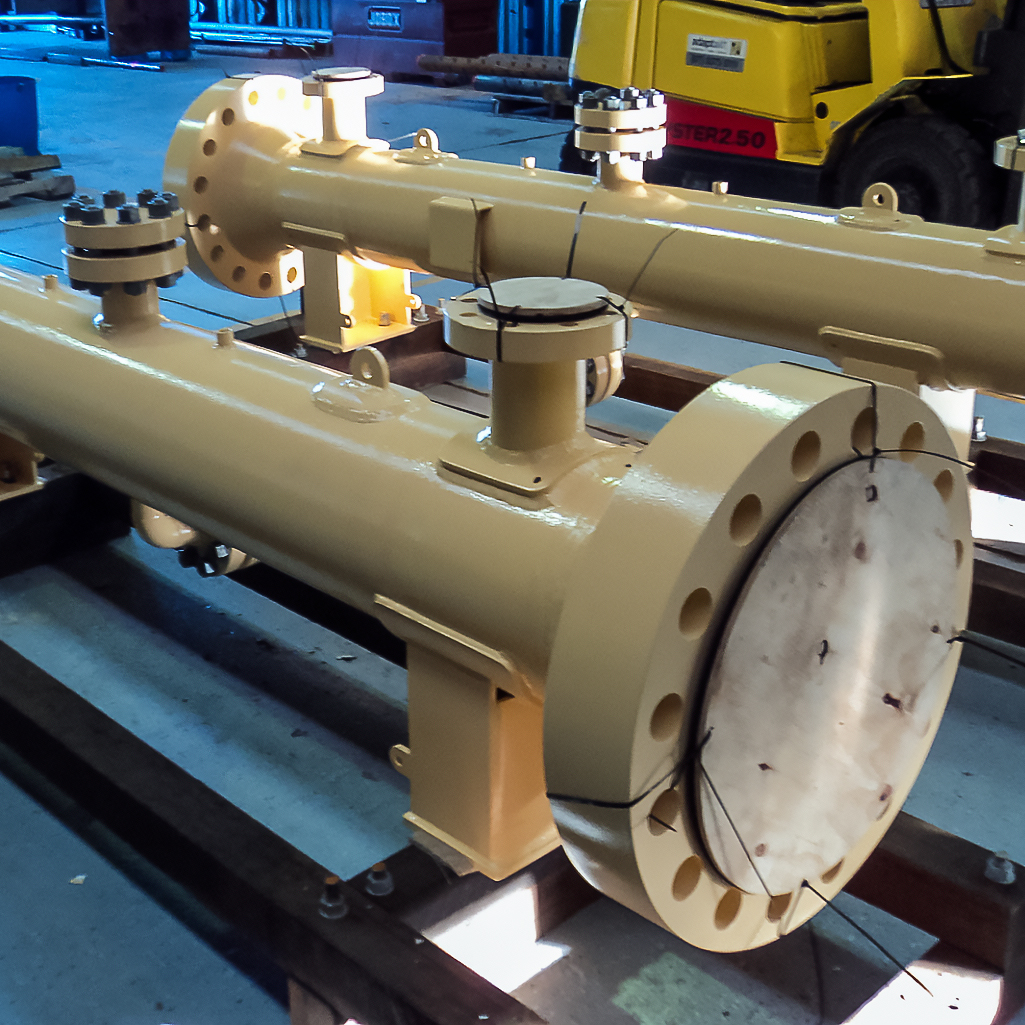

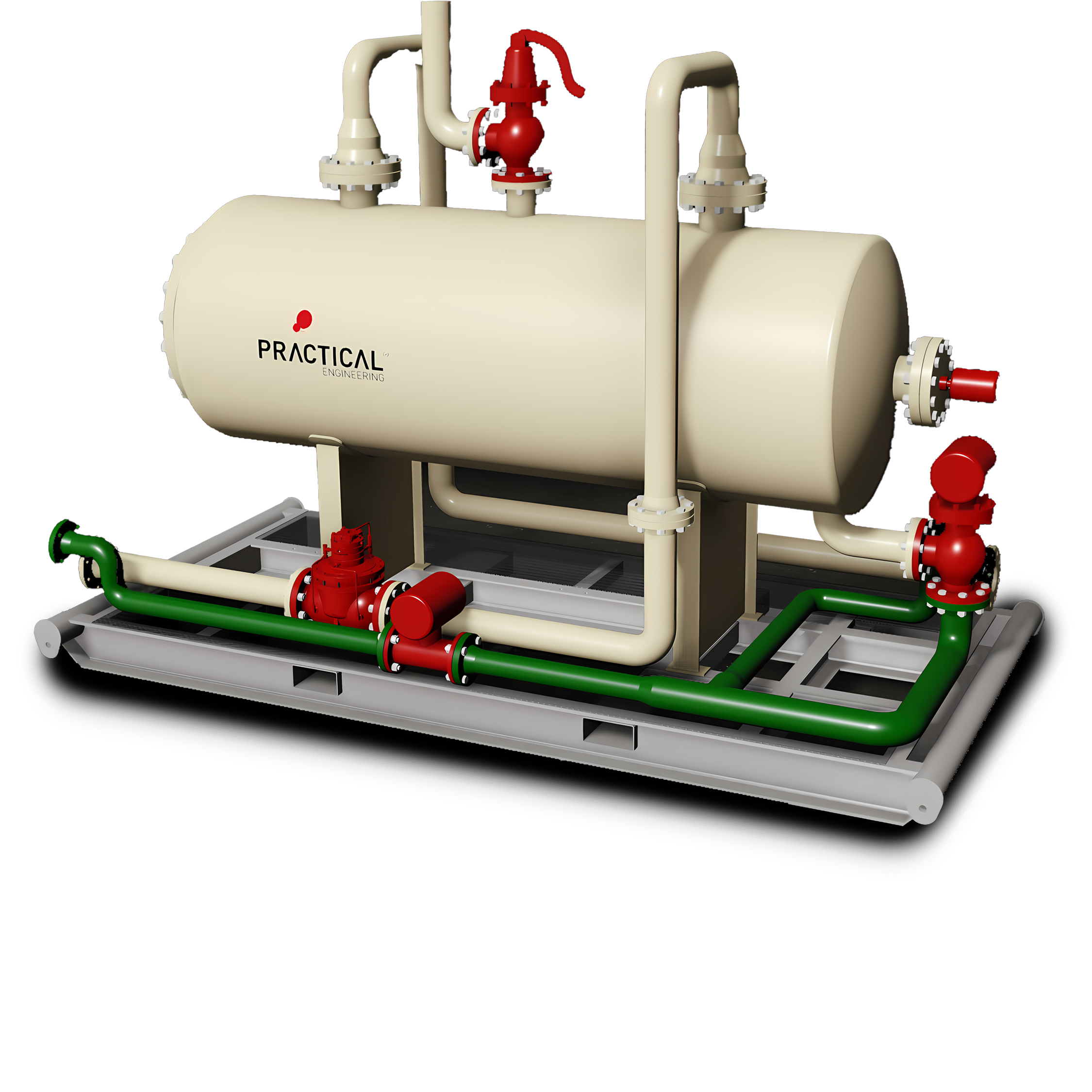

Practical Engineering offer pressure vessel design services from concept through to Issued For Construction and have strong working relationships with pressure vessel fabricators and should you need assistance to manufacture you vessel designs.

Typical design services for vessels will include:

- Consulting services to offer guidance and assistance through the design process.

- Engineering design to relevant Australian or International Standards.

- 3D modelling and 2D drafting for manufacture.

- Preparation of a Designer statement for Plant Design Registration.

- Manufacture of pressure vessel and project management.

- Advice on fabrication requirements such as NDE, post-weld heat treatment, leak testing, surface protection, inspections and more.

Practical Engineering can provide Designer statements for Plant Design Registration submissions to the relevant state or territory Work Health & Safety authority.

DESIGN VERIFICATION

Pressure vessel design verification is required for all pressure vessels needing Plant Design Registration and is the process where an existing pressure vessel design, typically approved by a RPEQ engineer, is verified by a second engineer, typically a RPEQ engineer with competence in the verification of pressure equipment.

Typical design verification services will include:

- Consulting services to offer guidance and assistance through the design verification process.

- Design verification to the relevant Australian or International standards such as AS 1210, AS 1228, AS 2030.1, ASME BPVC Section VIII Division 1, EN 13445 and GB 150 to name a select few.

- Preparation of a Design Verifier statement for Plant Design Registration.

- Submission of Plant Design Registration application to the relevant state or territory Work Health & Safety authority.

We provide in-house pressure vessel design verification to AS 3920. Our ISO 9001 accreditation permits both design and design verification of pressure equipment internally, without the need for you to engage 3rd party consultants, making Practical Engineer your one-stop firm for pressure vessel design and design verification.

Our design verifiers are highly skilled RPEQ engineers, registered on the National Engineering Register in the special area of practice of pressure equipment design verification.

Do I need Plant Design Registration?

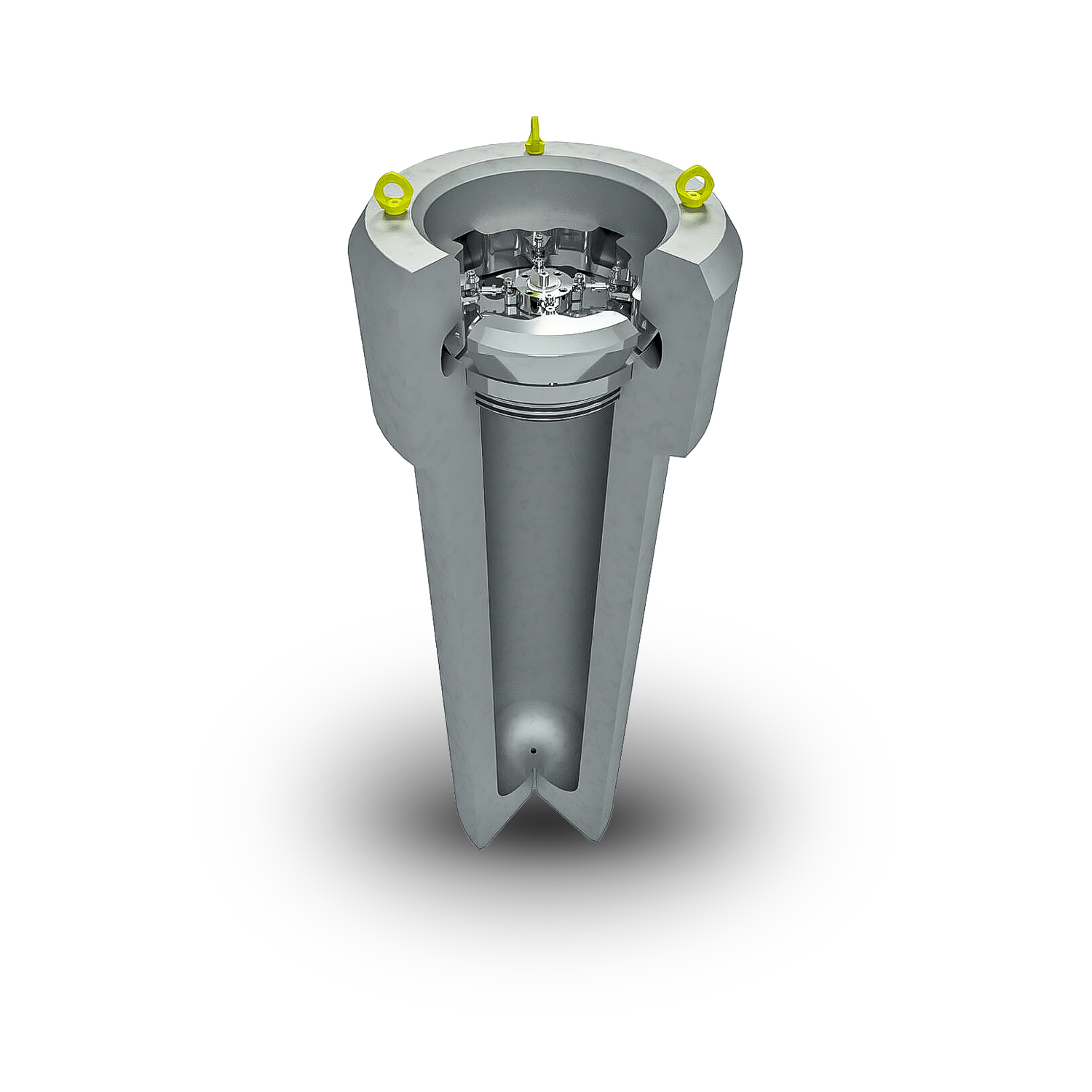

Certain types of plant design require registration under state and territory Work Health and Safety regulations. Pressure vessels fall within this category as they are major hazards to their surrounding environment, typically used to store their contents at elevated pressures and temperatures with explosive potential, requiring the utmost attention to detail throughout the design process. Plant Design Registration requires design verification of the plant’s design and speaks to the need of having multiple sets of eyes review these high-risk designs.

The legal requirement for Plant Design Registration is discerned by the “Hazard Level” determined from an assessment to AS 4343, attributing a Hazard Level of A, B, C, D or E to the vessel based on its stored potential energy and other risk factors, “A” being attributed to vessels with the highest level of risk.

Should your vessel be assessed as Hazard Level A, B, C or D, your application will require Plant Design Registration and pressure vessel design verification.

Unsure if you need Plant Design Registration? Contact us and we will discuss your project-specific requirements.

Do I need Plant Registration?

Plant Registration is required for pressure vessels with a Hazard Level of A, B or C, and requires that each manufactured vessel has been inspected by an approved inspector and is fit for service.

What about imported pressure vessels?

Imported plant is subject to the same requirements as plant manufactured within Australia, and may require Plant Design Registration and Plant Registration.

Contact us to discuss your specific circumstances and your potential obligations.